Uživatelské nástroje

Umístění: CeMaS » CeMaS (English) » Projects » Thermopot » Construction of Thermopot Using Magnetic Induction

Postranní lišta

en:projects:thermopot:magneticka_indukce

Obsah

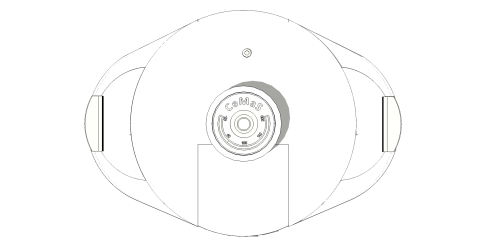

Construction of Thermopot Using Magnetic Induction

This version of thermopot is usable on magnetic induction cookers.

Body

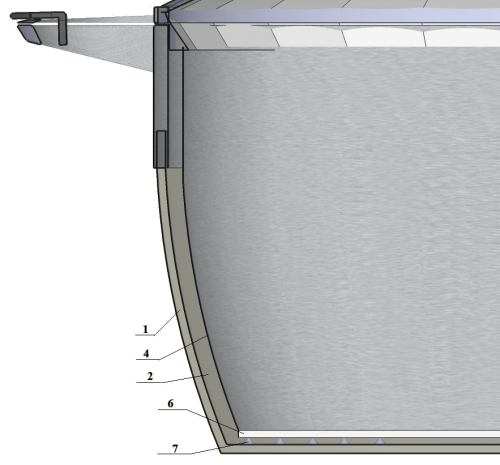

Inner Shell

- Composed of uniform food-grade material with good thermal conductivity to dispatch heat effectively. We recommend food-grade stainless steel (number 4 on cross-section) or copper.

- There is ferromagnetic plate (number 6 on cross-section), thermally connected (eg. with metal weld) to inner side of ideally flat bottom, acted upon by induction heating underneath and that is why mutual distance must be minimal for effective induction.

Outer Shell

- Bottom part should be composed of non-magnetic material to prevent heat induction. We recommend to make the whole outer shell from glass (number 1 on cross-section).

- Top part may be decorated with band from metal or plastic (number 5 on cross-section).

- Because outer shell is warm only during cooking (with temperature under 40 °C), it is important to use thermometer connected with inner shell and leading out through outer shell to show temperature of content being cooked.

Insulation Gap

- This insulation gap is located (number 2 on cross-section) between outer and inner shell.

- It serves to insulate heat inside the pot.

- It can be in the form of vacuated interspace. manometer may be installed to show pressure in this gap and allow vacuum state checking. Space should be vacuated as much as possible, but there is a need to take stability of pot construction into account to prevent its deformation, which may require addition of supporting elements with small thermal conductivity (eg. glass) between inner and outer shell (number 7 on cross-section).

- It can also be filled with thermally insulating (eg. inert) gass like in construction of insulating glass to prevent vacuum underpresure in the gap.

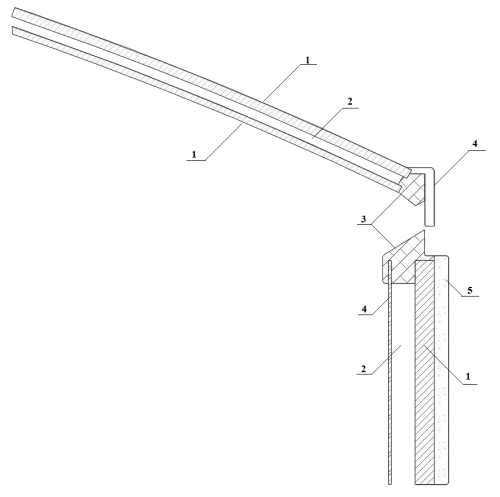

Insulation Sealing

- located (number 3 on cross-section) between outer and innder shell

- Rims of both shells are connected with durable sealing with small thermal insulation and enough solidity to ensure construction stability.

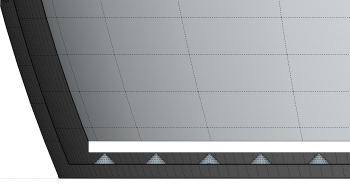

Lid

It is composed of similar double shell construction as pot body:

- Outer and inner shell from suitable materials like glass (number 1 on cross-section), metal, plastic etc. Inner shell should withstand temperatures above 150 °C.

- Insulation gap (number 2 on cross-section) and sealing (number 3 on cross-section) are the same as in pot body.

- There may be also thermometer installed in the lid.

It contains additional hole mounted with either

- pass-through vent for steam conduction from pot inside out or

- relief vent in case of lid hitching to pot body with locking mechanism in lid handles and using the pot as presurized one when vent plays a role of safety function for conducting overpresure out of the pot.

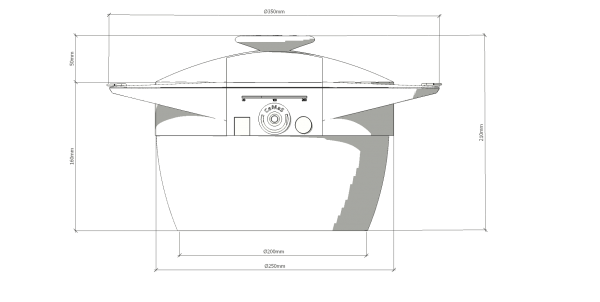

3D Model

Tomáš Bytčanek from Čadce in Slovak Republic is author of model and graphics of thermopot. The price of developing the model was 230 € due to friendship.

Model is available in these formats:

Authors

This document was prepared by CeMaS company thanks to these people:

- Ján Striček

- Radovan Striček

- Marek Ištvánek

- Tomáš Nešpor

- Tomáš Sousedík

and was completed in March 2018.

en/projects/thermopot/magneticka_indukce.txt · Poslední úprava: 26.03.2025 17:08 (upraveno mimo DokuWiki)